5 Common Uses for Webbing Slings in Rigging

Webbing slings are very critical equipment with regards to rigging and material handling since they offer light, flexible, and very robust solutions in liftings, securing, and maneuvering loads. In order to offer the secured and dependable alternative to traditional chains and wire ropes, webbing slings are made from high-strength synthetic fibers. Valuable webbing slings for protection on delicate or fragile loads, reducing weight during liftings operations and improving handling efficiency.

This section will describe five basic and widely used applications of webbing slings in rigging and how it promotes safe and efficient lifting in various industries. These examples bring focus on webbing slings in simplifying and enhancing operations for them to be a highly popular application within the professional fields.

-

Heavy Machinery and Equipment Lifting

Probably one of the most common uses for webbing slings is in the lifting of heavy machinery and equipment – an exercise prevalent in construction, manufacturing, and logistics. Webbing slings are made for high loads and easily provide the level of strength needed to facilitate the safe lifting and movement of machines of varying shape and weight. The flexibility will be given an appropriate snug fit around irregularly shaped equipment that can sometimes prove extremely difficult to raise with more rigid materials such as chains or wire ropes.

Advantages of Using Webbing Slings When Lifting

– Flexibility: Webbing slings can be wrapped around equipment having odd shapes, therefore making it stable and balanced during lifting.

– Less Abrasion: Webbing is softer than metal and tends not to scratch off the surface of the machinery.

– Lighter Weight: Webbing slings are light in weight and hence easy to handle with positioning, a particular advantage in high-mobility operations.

Webbing slings are mainly used at construction sites and industrial facilities in combination with cranes, hoists, or other lifting equipment. These slings can be made of the following materials: ropes, wires, chains, and straps made from natural fibers, synthetic fibers, or a combination of both. Webbing slings are secure methods of maneuvering heavy equipment to prevent instability and reduce the chance of accident.

-

Securing Loads During Transport

Webbing slings are commonly used for lashing loads during transportation, especially in freight, shipping, and trucking operations. Lashing cargo is vital in transportation, especially when moving products along roads, railroads, or oceans to prevent movement and damage to the cargo items. Webbing slings are a powerful, non-abrasive method of restraint for almost any type of cargo, including palletized shipments and large containers.

– Load Protection: The soft surface of webbing slings provides protection to cargo from damage even when tied down tightly.

– High Tension: Webbing slings which have the capability of holding some significant amount of tension for very high speed or a tough environment

– Elasticity: These have slight elasticity in them that absorbs shocks and vibrations thus stabilizing cargo within the vehicle.

Webbing slings are highly valuable in the securing of sensitive and fragile loads, for example, electronic equipment or artwork. It is avoided as much as possible to use traditional metal chains or straps which may cause damage on the surface. They are usually linked with a ratchet lashing system to produce a robust, variable restraint ensuring that cargo arrives at the destination in one piece.

-

Hoisting Fragile or Delicate Materials

Webbing slings are ideal for the lifting of fragile and delicate materials liable to surface damage and breakage. They are best suited both for lifting glass panels, marble slabs, polished metal sheets, and other materials that may easily get damaged by harder lifting gear. These often employ spreader bars with them where they distribute load rather than having a concentrated pressure point or points that would crack or deform delicate materials involved.

Advantages of Webbing Slings in Carrying Fragile Goods:

It shields the surface from scratches, chipping, or cracking since webbing slings contain soft fabrics.

Load distribution happens when webbing slings apply either the basket or choker hitches. This would further minimize the stress created to fragile materials.

Adjustment is possible because webbing slings are flexible thus operators can fit around the cargo with precision and less force applied.

In glass manufacturing, architectural projects, and fine art logistics, for instance, webbing slings are sometimes the preferred method of hoisting and moving sensitive goods. They prevent companies from wasting stock or incurring costly repairs or replacement due to damage caused by possible surface contact.

-

Construction and Structural Assembly

It is very handy for the lifting and positioning of building materials such as beams and steel, slabs, and prefabricated components in construction and structural assembly. This material is light but has the ability to carry this type of load and yet easy for the rigging person to make such a handling; it is quite different when using chains.

It then becomes easier for a construction team to manage when they are working in a tight area or from high elevations.

Advantages of Webbing Sling in Construction:

– Ease of handling : Webbing slings are lighter than chains and wire ropes, so they could be moved more easily, particularly in big construction sites.

– Versatility: Its strength and flexibility make it possible to use them when lifting different types of construction materials and other components in a construction project

– Increased Safety: Construction loads are less likely to swing or shift in their position, which would probably cause accidents on the construction site.

Many construction projects use webbing slings in lifting beams and other structural elements for high-rise assembly. These improve the efficiency of the rigging operations, especially when navigating materials through narrow openings or small areas. Also, webbing slings prevent damage to sensitive surfaces on prefabricated parts, which is an advantage of modern methods of construction where most elements are pre-finished prior to delivery.

-

Marine and Offshore Operations

The marine and offshore environments have unique requirements for special lifts since they suffer corrosion from saltwater and humidity. For a marine application, webbing slings made with synthetic fibers such as polyester or nylon are suitable, as they are resistant to corrosion and subjected to the harshest rigors. In oil rigs, shipping docks, and shipyards, webbing slings are broadly used for lifting and relocating cargo, machinery, and other equipment.

Key Benefits for Marine Use:

No Corrosion When Exposed to Salt Water With salt water, webbing slings do not corrode like metal chains. This makes them perfect for marine environments.

Much Lighter in Weight and Buoyant Webbing slings are even lighter than their metallic counterpart and float. This is very beneficial in water-based operations.

Easy Storage and Maintenance: They are easy to store and maintain because they require no special treatment in order to avoid rust or corrosion.

Primarily webbing slings are used in the loading and unloading of vessels, transferring gear on the offshore platforms, and moving equipment from the docks. It is a very efficient means in maritime environments where actual lifting machinery might be at risk for corrosion.

Selecting the Proper Webbing Sling for Your Application

The proper selection of webbing sling plays a crucial role in maintaining safe and efficient operations. The following guidelines should help you select the appropriate webbing sling for your application:

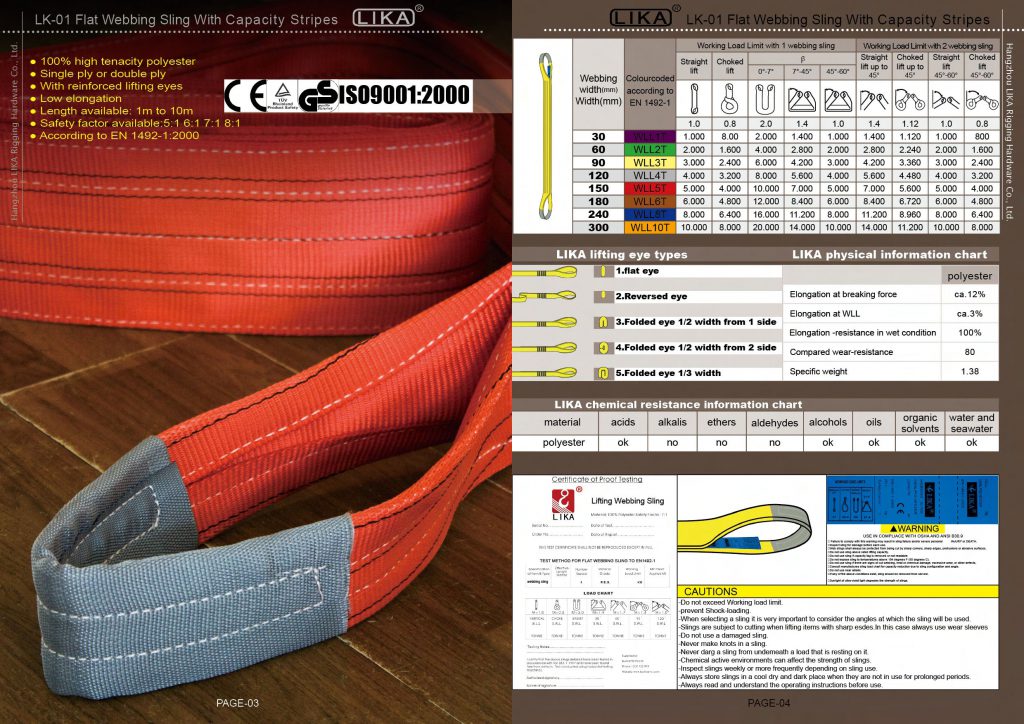

- Strength to Carry a Load: Every webbing sling has a capacity for loading, and most of the time, color code is used to indicate the maximum weight that can be carried with a sling. When purchasing one, you should look out for the ability to provide the weight of your load.

- Width and Length: Choose a sling that is the right length and width to fit the size of the load and the vertical height of the lift. Wider slings have better distribution in loading and are good when carrying fragile materials, while narrower slings are suitable for smaller, compact loads.

- Material: Webbing slings are mainly made of synthetic material, such as polyester, nylon, or polypropylene. Polyester slings resist the high UV and moisture quantities and can be applied outdoors. Nylon slings exhibit much better elasticity, which is beneficial for dynamic loads and elastic shock absorption.

- Environmental Conditions: If the environment of your operation is corrosive or moist, you should look for a webbing sling that meets those conditions. Many slings are treated with coatings which provide additional abrasion and chemical protection against UV exposure.

- Inspection and Maintenance: The webbing slings should be subjected to inspection for good condition. Check for wear signs, frays, and damage and discard any sling that displays noticeable signs of wear.

Maintenance and Safety Guidelines for Webbing Sling

To guarantee long term usage and safety of the webbing sling, here are some guidelines on its maintenance and safety precaution:

– Weekly Inspection: Inspect webbing slings every time you go to use them for signs of wear, fraying cuts, or damage. A little bit of damage can quickly incapacitate a sling; thus, replace all slings showing signs of decay.

– Storage of Webbing Slings: Store webbing slings in a cool, dry place away from the damaging rays of the sun or chemicals that may degrade the fibers. Do not hang up slings on sharp edges or on abrasive surfaces to avoid abrasion.

– Proper Use of Hitching for Webbing Sling There are three types of hitches to be made using a webbing sling namely basket, choker, and vertical hitches. Choose the proper hitch to use if you want to have a stable and balanced operation.

– Don’t Overload the Sling Use the sling only with its rated capacity so that you can avoid unwanted accidents and secure the lifts. Never lift a load that is about to exceed the rated load limit of the sling.

Conclusion

Webbing slings are versatile and indispensable tools in applications of rigging that offer flexibility and strength and toughness in all kinds of industries. Among lifting heavy machinery, securing delicate cargo, or getting tasks done with the construction, webbing slings have actually improved safety and efficiency in all kinds of lifting operations. Choosing the right webbing sling and observing proper maintenance will let you maximize performance from these indispensable tools to support even safer and more efficient rigging operations.