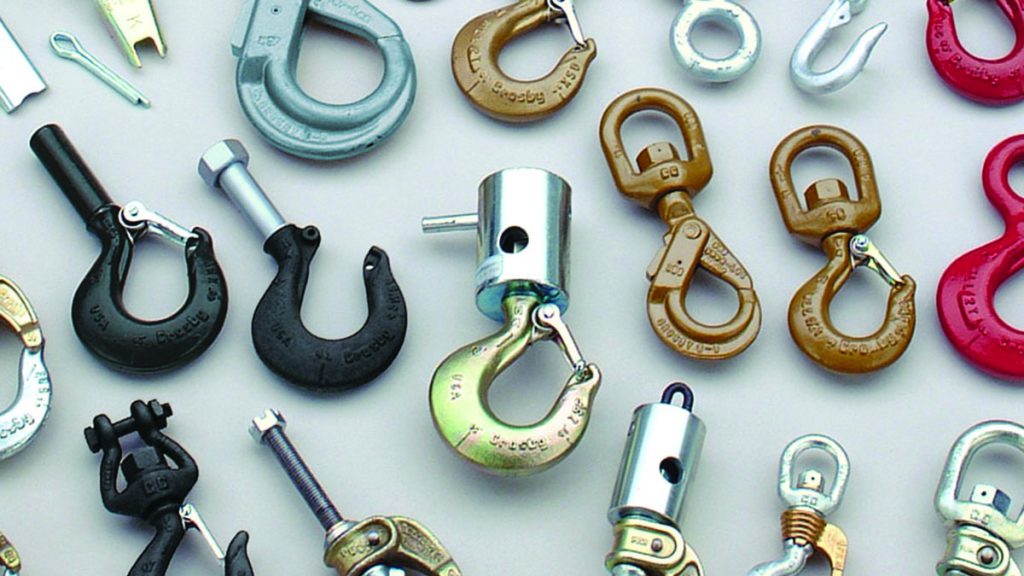

Different Shackles: Screw Pin versus Bolt Type Shackles

Shackles probably rank among the most ubiquitous and critical rigging, lifting, and securing chains, cables, and ropes to equipment or anchor points. These are tinylooking devices yet so important for the connection and securing of various pieces of equipment or base points. The shackles, no matter how deceptively simple, play a vital role in the safety and reliability of lifting operations across an array of industriesfrom construction, maritime, oil, and gas as well as handling heavy pieces of equipment.

While selecting shackles, you must know the types of shackles; apart from that, the two most common types are Screw Pin Shackles and Bolt Type Shackles. These two kinds basically serve the same purpose but differ in design, application, and safety features. Here, we intend to show you the differences between the two types of shackles. This will enable you to decide the type that best suits a specific application.

What is a Shackle?

Before we detail screw pin and bolt type shackles, we need to present some ideas about the general definition of a shackle. In terms of equipment used in lifting, securing, or towing, a shackle is actually a metal fixative that is used to join one piece of equipment to another. Shackles are designed for heavyload operation and are commonly made from highstrength steel for withstanding the wear and tear, and momentary unexpected overloads.

There are different types of shackles; however, the commonly used are anchor shackles, bow shackles, chain shackles, and dee shackles. Shackles come in a range of sizes, materials, and configurations, depending on application.

However, since most materials are tolerant to some degree in cases of overtightening during installation, it is often ignored. Screw pin shackles are provided with a button or mechanism that prevents screws from being excessively tightened during installation.

Pin screw shackles, which are also called pin shackles, have the most diversified application in different sectors including the maritime, construction, and industrial sectors. The distinguishing characteristic of the screw pin shackle is the ability to have a removable pin, which is inserted in the body of the shackle with the help of screwing action.

Screw Pin Shackles Design and Configuration

A screw pin shackle usually comprises a U shaped body, commonly referred to as the “bow.” It is attached to a pin that screws in to close the shackle. The pin could comprise a small thread or groove to prevent its loosening while use is in progress.

Features of Screw Pin Shackles:

- Screw Pin Mechanism: The pin is screwed inside the body of the shackle, hence ensuring that it gets locked in tightly. A wrench is usually applied when tightening the pin so that it does not work free in the field.

- Ease of Assembly and Disassembly: Screw pins can easily be unscrewed, thus versatile for such applications whereby temporary connections or frequent assembling and disassembling are needed.

- Low Cost and Accessibility: Screw pin shackles are relatively cheaper, and their sourcing is much easier in the marketplace as compared to bolttype shackles.

- Safety Considerations: For added safety, screw pin shackles carry a feature of having a cotter pin or retaining clip so that under tension or load, the screw pin cannot fall back.

- Corrosion Resistance: Screw pin shackles are available in many corrosionresistant materials, such as stainless steel or galvanized steel, and can therefore be used in hostile services like marine or offshore environments.

Applications of Screw Pin Shackles:

Marine and Offshore: In anchor systems, moorings, and other applications involving marine rigging

Construction and Heavy Equipment: Securing loads and connecting rigging in lifting operations.

Transport and Towing: Applied in tow type applications that involve quick and secure attachment.

Temporary Rigging Systems: Rigging systems that normally are applied in many rigging projects in which the rigging systems are to be installed and dismantled frequently.

Bolt Type Shackles

Bolt Type Shackles Also known as bolt pin shackles, these bolts have a much more permanent and secure connection mechanism compared to the screw pin shackles. They simply replace the bolt and nut assembly with the threaded screw pin that fastens the pin in place.

Design and Structure of Bolt Type Shackles

The most obvious distinction between bolttype and screw pin shackles is in the mechanism used to attach the pin. Bolttype shackles feature a bolt, threaded all the way through the body of the shackle, and on the opposite side attached with a nut. The design provides a much stronger, safer attachment especially in applications where the shackle will experience extreme forces or where safety is paramount.

Key Features of Bolt Type Shackles

- Permanent Connection: The bolt and nut mechanism comes as a more secure and permanent connection than one having a screw pin that may loosen with time

- Strength: Bolt type shackles are specifically designed for withstanding higher stress levels than the screw pin shackles, thus becoming the former stronger and durable, which are suitable for heavy usage.

- Rigorous Standards of Safety: Bolt type shackles are often deployed in safetycritical applications because their design is reliable and stands to a higher risk. The potential consequences of such a connection failure can be paramount.

- More Challenging Assembly Process: In contrast, bolttype shackles cannot be assembled as conveniently as a screw pin shackle. The assembly process takes longer than that of other types of shackles because the nut has to be tightened with the help of a wrench. This is not ideal for any application that requires speed removal or disassembly.

- Corrosion Resistance: Like screw pin shackles, bolttype shackles can be made of stainless steel or galvanized steel if it is intended for applications where there is a risk of corrosion, such as in marine or offshore operations.

Use of Bolt Type Shackles

Heavy Lift Operations: Used in industrial and construction applications involving high loads and requirements for security.

Harsh Environment Rigging: Suitable for situations where the shackle would be subjected to severe forces, thus requiring special rigging operations in places like oil rigs or at offshore structures.

Applications that involve safetycritical situations: Applications where the loss of the pin or fastener assembly due to loosening could put human lives or equipment integrity in jeopardy.

Permanent installations: Situations where a shackle would be operated for long service periods and was unlikely to require removal or change frequently.

Screw Pin vs. Bolt Type Shackles: Key Differences

Although screw pin and bolt type shackles serve the same purpose for similar operations, their design features are quite different. Suitable applications have made them suitable for different scenarios. Here is how screw pin and bolt type shackles are different in tabular form:

| Feature | Screw Pin Shackles | Bolt Type Shackles |

| Connection Mechanism | Screw pin mechanism which screws into place | Bolt and nut assembly |

| Ease of Assembly/Disassembly | Quick, easy to put together/tear apart | More complicated to assemble and tear apart |

| Strength | Sufficient for most applications but may not hold as good under extreme loads | Stronger, more secure, especially under heavy and safetycritical applications

| Applications | Temporary rigging, marine applications, and general lifting | Heavy lifting, industrial rigging, and safetycritical environments |

| Corrosion Resistance | Available in stainless steel or galvanized steel | Available in stainless steel or galvanized steel |

| Cost | Generally more affordable | Typically more expensive due to the higher strength and durability

| Safety Features | Some models feature a retaining pin or clip for extra security | Further secured and less likely to loosen through the bolt and nut construction |

| Durability | For most general applications | Better suited to heavyduty, extended service periods |

Choosing the Best Shackle for Your Needs

When choosing between screw pin and bolt type shackles, some factors must come into play:

- Loading Requirements: Bolt type shackles are highly advisable for extreme heavy loads and safetycritical applications as they provide a solid and secure linkage.

- Frequency of Usage: Screw pin shackles are preferred if the connection has to be disassembled frequently. These are faster and easier solutions.

- Environment: Where screw pin and bolttype shackles are both offered in corrosionresistant stainless steel versions, an application may call for one over the other for use.

4.Safety Factors Bolttype shackles have the advantage of failure being catastrophic when failure would be catastrophic; failure would require wrenching apart the bolt and nut to open.

- Cost and Budget: Screw pin shackles are generally cheaper, so if you’re working with midpoint loads and need a budget choice, then you might find one of these suitable.

Conclusion

Shackles are integral components in rigging and lifting operation in handling and securing loads, and the right selection of shackles for your needs will play an important role in determining the success and safety of your operations. Screw pin shackles are perfect where highspeed coupling and uncoupling is required besides serving for moderate load applications. As against bolttype shackles offer snug and secure connection, and thus perfect for heavyduty lifting, safetycritical applications, or harsh environmental conditions.

Both shackles have different advantages and knowing its characteristics, strengths, and weaknesses would help you narrow down your decision in choosing which one best suits your needs. When choosing a shackle, safety always comes first, and the type of operation is also to be considered.

Hence, understanding the differences between screw pin and bolt type shackles ensures both the issue of safety in rigging and lifting operations and the attainment of efficiency.