Enhanced Safety with Quality Bearing Swivels

No doubt, heavylifting and rigging operations always bring the safety factor into sharp focus. Whether you are shifting heavy industrial equipment, in construction, or managing a logistics operation, you have to be certain that all parts of your lifting system are at their best quality. Bearing Swivels play a vital role in furthering both the efficiency as well as ensuring safety of operations in lifting.

Bearing swivels are specialized mechanical equipment with the primary intention of rotating freely and not overstraining the balance of the general lifting equipment. It promotes smooth control of rotations free from twisting movements, reduces gear wear on ropes and chains as well as loads stabilization. However, just as with all equipment, proper selection, maintenance, and usage will make the bearing swivel perform better and devoid the possibility of safety hazards.

In this blog, we’ll explore the role that bearing swivels can play in lifting operations, discuss the value of using highquality bearing swivels, and describe how that can contribute to a safer, more efficient lifting environment.

What Are Bearing Swivels?

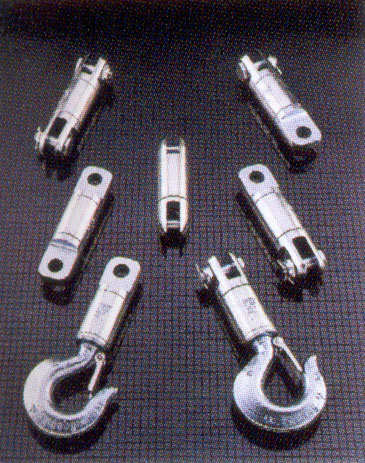

A bearing swivel is a mechanical device that provides the pivot between two interconnected components with the load in a fixed position. A bearing swivel has its most common application in lifting, hoisting, and rigging operations where the load might need to turn around to its desired position either upwards or downwards. The main intention of a bearing swivel is the smooth, hitchfree rotation without twisting or tangling of the lifting line or chain.

Bearing swivels primarily consist of an inner rotating component called the bearing and an outer housing which allows the device to freely revolve while it shares a part of the weight load. In reality, these swivels have been composed of strong materials such as steel or stainless steel. They have been designed this strong, so they can withstand the tremendous stress a lifting operation can induce, thus ensuring stability and security.

Why Bearing Swivels Are Vital for Safety in Lifting Operations

Lifts are not straightforward and especially complex when doing heavy loads that will not easily fit on an imaginary ‘best suited’ geometric shape. Without the correct equipment, the lifting line can twist, which leads to a few potential risks. Bearing swivels prevent rope or cable twisting, which is very important for the following reasons:

-

Preventing Load Twisting and Tension

In the case of heavy loads, loads lines can twist through tension, more so when they are located offcenter or if their direction becomes unpredictable. Heavy twisting of the load could provide dangerous positions such as those listed below.

Sudden jerks: When the load is knotted, or the line has twisted, it may jerk the rope abruptly and create strain on the lifting system, which, at times, causes a sudden jerk or even breaks down equipment.

Uneven Load Distribution: Rotation of the load can cause the weight of the load to distribute unevenly which contributes to the part that the load can tip or become unstable in lifting.

Problems that these removals bring since bearing swivels are free of rotation, will enable the load to balance and prevent shocks that might disfigure equipment or present a hazard for workers.

-

Least Wear on Lifting Ropes and Equipment

Constant twisting and friction can destroy lifting lines, ropes, and chains quickly as they wear out early, leading to reduced functionality and shorter lifetimes. Using highquality bearing swivels in the lifting system ensures smoother rotation; therefore there will be less friction between the rope or chain with the lifting mechanism.

This leads to

Extended lifespan of lifting lines: Reduced friction and twisting allows the lifting cables and ropes to have a more extended life expectancy.

Lower maintenance cost: The components experienced minimum damage as their repairs are minimized

Longer equipment lifespan: Also, the lifting hardware such as hooks, pulleys, and winches undergo a lesser strain and thus have an extended lifespan.

-

Stabilizing Load

Second, bearing swivels promote stability of loads. The main point behind lifting big or heavy loads is ensuring that the loads do not pose risks of accidents. A bearing swivel ensures that the load rolls with free rotation and comes to rest in a stable position when being lifted without swaying, shifting, or unbalanced movements that can raise a threat to the safety of workers.

Benefits of a HighQuality Bearing Swivels

Even though bearing swivels are such an ordinary component in many lifting and rigging applications, choosing a good quality swivel can greatly impact safety and performance. The following are some of the benefits of using highquality bearing swivels.

-

Improved Safety Performance

The primary benefit of quality bearing swivels is their contribution to safe conditions. Lifting applications make use of the swivels to balance and make loads stable over the entire process. They shun disastrous twisting and jerking movements, which could come when lowquality or wornout swivels fail to execute properly.

Highquality swivels are less likely to cause overloading or damage to the lifting equipment due to smoother rotation and less resistance.

This consequently means that malfunction of equipment leads to reduced chances of system failure or accidents.

-

Enhanced Resilience and Reliability

Bearing swivels of high quality are made out of materials like carbon steel or stainless steel, all highly durable and resistant to corrosion. This provides an added advantage over other uses since it can be used fulltime in construction sites, offshore operations, and warehouses, bearing lots of moisture, chemicals, and heavy loads in some places.

An expertly made swivel will be very adequate for everyday use, and the internal bearings will rotate smoothly even with load applied, providing smooth continuity of usage without interruptions. They suffer less with problems like jamming or freezing, characteristic features of cheaper swivels.

-

Accuracy in Design for Better Performance

With highly graded bearing swivels, there is high accurate engineering that makes all parts, including the bearings, housing, precise in alignment to rotate with very smooth friction and stress, hence performance, therefore lowering the possibility of failure. Better deals are made with maximum load capacities, and highgrade swivels work within a wider application range.

-

Corrosion Resistance

Exposure of water, chemicals, or weather may result in corrosion weakening the equipment over time. The stainless steel bearing swivels excel in corrosion properties; thus, it is suitable for application where there is extensive exposure to outdoor and marine environments. The strength and integrity are sustained since there is no room for corrosion and rust.

When you are choosing bearing swivels, such as those for lifting, you desire to have products that abide by the sector standards for safety. A high quality is able to check up on loads limits and rules for safety compliance. This means the product is safe for use, reliable, and will perform as expected during expected loads.

Choosing the Right Bearing Swivels for Your Needs

To get the most from bearing swivels, you must choose the right kind that suits your necessary lifting. Choose a bearing swivel by considering the following factors.

-

Load Capacity

Select a bearing swivel capable enough to handle the weight and load capacity needed for your lifting operations. Ascertained from the manufacturer’s specifications, maximum working load limit, to avoid overloading the device.

-

Material and Coating

For added strength and resistance to corrosion, use a bearing swivel that is made up of highstrength material such as stainless or carbon steel. If exposed to extreme weather or chemicals, ensure that it has a corrosionresistant coating to make the life of the swivel longer.

-

Design and Features

The actual designs of bearing swivels are different for various lifting operations. There are swivels that lock during disengagement to prevent unintended disengagement. There are those with heavyduty design while others for offshore lifting. You should, therefore, choose the right swivel for your operation and with its benefits in safety.

-

Conformity with Standards

Always opt for bearing swivels that meet the safety requirements of the industry. In this way, you will surely get to understand that they are reliable for heavyduty lifting operations as it meets the requirements of industry safety.

Conclusion

Super highquality swivels for the bearings greatly contribute to lifting and rigging safety as well as efficiency. These parts facilitate smooth turning so that there is no twisting at all and tend to wear away the lines while lifting, stabilize loads with a high coefficient, as well as provide them with the necessary protection to the integrity of the whole system as such. The perfect bearing swivel shall be of durable material, meant for the required load, and comply fully with all the safety norms. In this manner, one would ensure the lifting safe and reliable operations.

This will be avoided as much as possible, with the right equipment and with a quality approach to the lifting operation. Safety always comes first and, for example, good quality bearing swivels is an investment that will pay off in performance but, over the long term, which is a great advantage.